Ash and Slag handling

Ash silos from 50 m3 up to 1000 m3:

The ash silo is built with a standard silo bottom, with a sliding frame and discharge screw. For smaller volumes a silo top is built with the same diameter as the bottom.

For larger volumes a cone is built over the silo bottom. The main silo is then placed over the cone.

Screw bins for ash:

A small bin over discharge screw. The volume is controlled by level control.

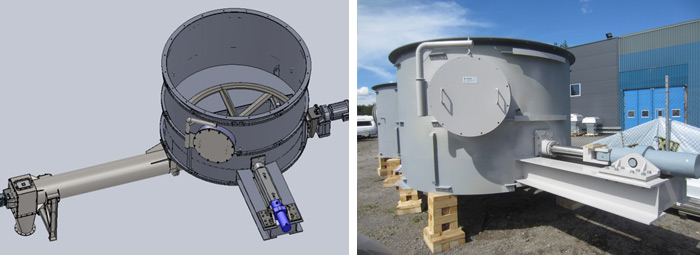

Discharge for fly ash:

Silo bottom with sliding frame and discharge screw.

Conditioning of fly ash:

Container systems:

Saxwerk design customized containers for storage of dry fly ash.

Sub merged conveyors underneath combustion plants:

Underneath the furnace a sub merged conveyor is placed to take care of ash and slag.

Product list:

Ash and Slag handling

ROTORS »

» Hydraulic Rotor

SCREW CONVEYORS »

» Transport Screws

» Discharge Screws

» Vertical Screws

» Stoke Screws

» Special Design Screws

ELEVATORS »

» Belt Elevators

» Chain-Elevators

CHAIN CONVEYORS »

» Chain Conveyors, double chain

» Sub Merged Conveyors

» Redler type “Wet”

» Redler type “Dry”

ASH CONDITIONING »

» Conditioning with special flights

SLIDING FRAMES »

» Sliding Frame, standard

» Sliding Frame, special design

SILOS »

» Round silos

PUSH FLOORS »

» Push Floor, standard

» Push Floor, special design

» Reciving Bins